Pixhawk无人机教程-3.1.4 DJI F330 FlameWheel

APM:Copter参考手册目录3.1.4-DJI F330 FlameWheel

DJI F330 FlameWheel QuadCopter AssemblyThe DJI F330 FlameWheel is inexpensive, sturdy and small.Frame and Motor AssemblyESC Installation and Soldering the Power Distribution BoardReduced Vibration Installation of the Flight Control BoardGetting Ready to Fly参考手册目录

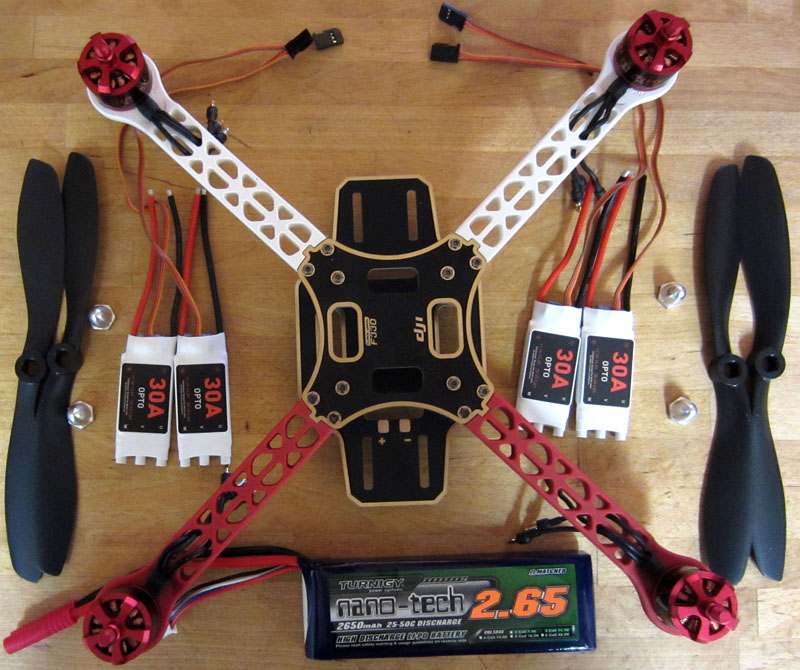

DJI F330 FlameWheel QuadCopter Assembly

The DJI F330 FlameWheel is inexpensive, sturdy and small.

It can be flown indoors or out.

Even though it is compact, the F330 is substantial and can easily carry a battery that will permit 15 minute flights.

Replacement parts and accessories including raised landing gear and tilt and roll controlled camera mounts are readily available.

The F330 can easily carry a GoPro type camera or FPV system if desired.

It is widely available in ARF (Almost Ready to Fly) form including Motors, ESCs (Electronic Speed Controls) and Propellers.

The DJI Motors and ESCs provided in the ARF kit are of high quality, and are rugged and long lasting so this is a recommended purchase.

In addition to the ARF kit you will also need a Flight Control Board (APM or PX4), a 5+ channel radio receiver, 5 female to female 3 wire receiver cables, a 3 cell !LiPo battery, a 3+ amp BEC (power supply), a battery strap, tie wraps and some assorted hardware.

You will also need, a good adjustable soldering iron, rosin cored solder, blue or purple thread locker and a set of small Metric Allen wrenches.

Frame and Motor Assembly

Go to the DJI web site Flamewheel support section (Here!) to get a PDF copy of their “manual” none is included with the Copter kits. It is more of an assembly diagram than a manual, but the pictures are definitely useful.

The DJI instructions show soldering the ESCs to the Power Distribution Board (bottom frame plate) first in this example they were put in after frame assembly because it makes it possible to fit things more closely, but then does require a bit of creativity when soldering the ESC leads to the bottom plate / power distribution board. Your choice.

Use Blue or purple removable thread locker VERY sparingly on the threads of the Allen screws when you assemble the frame. Try to keep excess off of the plastic. Not actually achievable, but do the best you can.

The motor and frame screws have a shoulder on them and you need to tighten them all sufficiently so that the shoulder fully seats. A good method is to install all screws (with Locktite) loosely then tighten all the screws on each frame arm one at a time. Do this in one sitting.

When installing the motors, pre-bend the motor leads upward a bit where the exit the motor bottom so that the motor can sit flat. Have the leads exit towards the center of the copter (motor bottom screws are off set and it can only be installed 2 ways), toward the center is correct. The motor screws are short and it is tricky to start the first screw on the motor bottom, ensuring that the motor lead is not pushing the motor up helps. Use blue Locktite on each screw and install all 4 screws for a motor loosely and then tighten them.

Thread the motor leads down through the first 2 large frame member holes, or you can run them around the frame member if you prefer.

ESC Installation and Soldering the Power Distribution Board

Install the ESCs with tie wraps. Threading the Tie Wraps from front to back through the frame members and between the motor bullet connector sockets makes a neater and more secure installation.

Install the ESC power leads through the slot under the bottom of the frame member and then trim and solder them to the power distribution board. This is a little harder than the normal method of going around the outside of the frame members but it is neater and can provide a little additional battery clearance.

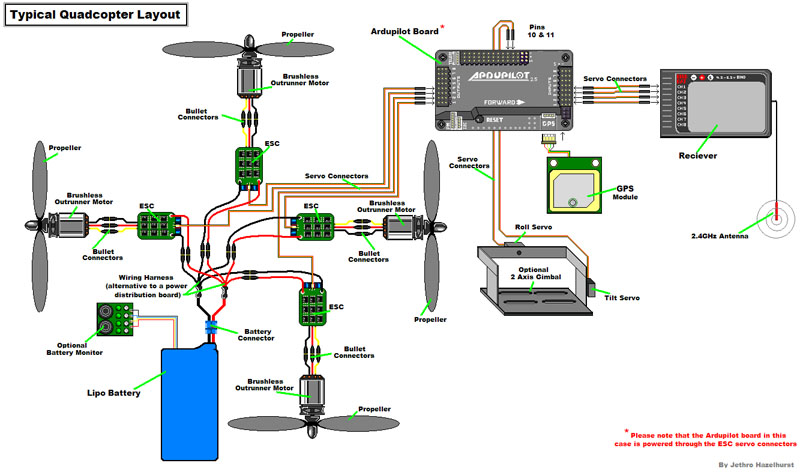

The above illustration shows a power distribution “Y” connector which is functionally identical to the !FlameWheel’s built in power distribution board.

When you solder the ESC and Battery power leads to the power distribution board you should flux and preheat both the pads and the wire in order to get a properly tinned (wet) solder joint. The board can soak up quite a bit of heat so set your soldering iron sufficiently hot.

If you are using the DJI ARF Flamewheel kit with the Opto ESCs you will need an external BEC because the Opto ESC’s do not contain a BEC. If you purchased an APM 2.5 board it comes with a power supply (BEC) you can use, other wise you will need to buy a BEC. Castle Creations makes an excellent and very reliable 10/5 amp BEC for about $20.00. Use a switching BEC in any case, they are more reliable and a lot more efficient than linear ones.

You do not need to and in fact can’t balance the DJI ESCs as shown elsewhere in the Arducopter Wiki, they are digital, optically isolated and are completely pre-balanced at the factory. Basically they work great out of the box.

Reduced Vibration Installation of the Flight Control Board

The current version of the ArduCopter APM flight controller firmware (and all future versions) requires that special attention be paid to removing as much vibration from the flight control board as possible.

This F330 FlameWheel has a special anti-vibration mounting of the APM which uses a folded over 1/16″ O-ring at each corner of the flight control board around a machine screw sticking out of a small standoff.

If you choose to use this method leave 1/10″ to 1/8″ clearance from each board corner for proper short coupled spacing. This will require minor surgery with a Dremel tool on each frame arm to achieve proper hole spacing in the top plate. Needless to say, remove as little as possible.

Alternatively a 3/4″ square of double sided adhesive backed anti-vibration gel such as Kyosho Zeal on each corner of the Flight control board will provide sufficient vibration dampening (1/10 to 2/10 G). Too much Dampening material is just as bad as too little or not enough. The flight control board is light so it only needs a small amount of dampening material.

Secure the flight controller with a Velcro strap over 1/2″ of soft foam in light tension. (Do NOT over tighten!).

Anti-vibration techniques, methods and “tuning” are covered in greater detail in the Anti-Vibration section of the Wiki: (Here!)

Compensation for Magnetometer interference from the motors is covered: (Here!)

Correct wiring of The Flight Control Board board and configuration for flight are covered extensively elsewhere in the Wiki.

The Velcro on the board and frame above is not in use and is not actually touching

Getting Ready to Fly

Our construction method allows the battery to be inserted between the two frame plates and this is an optimal location regarding the !QuadCopter’s center of gravity. The high quality 2650mah !LiPo Turnigy Nano battery used here is about as large as will comfortably fit, but it will permit 15 minute plus flights.

To prepare for the battery, the bottom frame plates power distribution solder joints should be covered with liquid electrical tape or silicone. Wrapping the battery in bubble wrap and taping it in place will provide additional electrical isolation from the solder joints and cushioning from vibration and sub-optimal “landings”. Use a Velcro battery strap through the frames bottom slots to retain the battery.

The stock 8″ DJI props that are supplied with the F330 ARF kit work fine. However the 330 !FlameWheel can definitely benefit from a 9″ prop (10″ will not fit on the F330). GemFan 9″ multirotor “Carbon Filled” props are only $2.00 each and are considerably superior to the stock 8″ props. They are almost impossible to break and the 9″ ones are considerably more efficient with these motors than the stock 8″ props.

The 9″ GemFan propellers are not made to fit the oval hubs of the DJI Motors, but you can carefully bore them out to about .31″ with an ordinary drill and they will fit perfectly. I use 11″ GemFans bored out this way on my FlameWheel F450. The bigger the diameter of the prop you can fit the more efficient it is all other things being equal and not exceeding motor or ESC maximums.

The ESCs and motor automatically disarm after 10 seconds without the motor turning. So anytime you have remained stationary (on the ground) for over 10 seconds you will need to rearm. This is a great safety feature.

You will need to load the Firmware to the APM and set up the various parameters in the Mission Planner as instructed elsewhere in this Wiki. (Do Not Attempt to Calibrate the DJI Opto ESCs and Do Not install the propellers until directed to do so)

To prepare to fly turn your transmitter on and plug in the battery , the ESC’s should emit a short series of musical notes and then be quiet. You are then ready to arm and fly.

A good set of starting PIDs for flying the !FlameWheel F330 in Stabilize Mode(as of ArduCopter version 2.9.1) are: Rate (Roll & Pitch) P = .09 and I = .045 and Stabilize (Roll & Pitch) P = 4.0

获取最新文章: 扫一扫右上角的二维码加入“创客智造”公众号